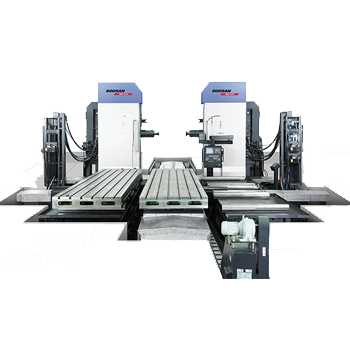

Double-sided boring machine for symmetric workpieces

- Bidirectional and simultaneous processing of long and symmetrical workpieces is provided via a double-column boring spindle for concentric drilling

- Table length can be increased depending on the size of the workpiece

Doosan DBD Series

- Table Size 1500x8000mm

- Travel (X/Y/Z/W) 8000/2000/450/500

- Max. motor power 26kW

Description

Specifications

| Sales Model | Unit | DBD 1270 | DBD 1580 |

|---|---|---|---|

| Spindle Or Quill Diameter | mm (inch) | - | - |

| Table Size | mmxmm (inchxinch) | 1250 x 7000 (49.21 x 275.59) | 1500 x 8000 (59.06 x 314.96) |

| Spindle Speed | r/min | 3000 | 2500 |

| Max. Spindle Moter Power | kW (hp) | 26 (34.9) | 26 (34.9) |

| Travel Distance X-axis | mm (inch) | 7000 (275.59) | 8000 (314.96) |

| Travel Distance Y-axis | mm (inch) | 1500 (59.06) | 2000 (78.74) |

| Travel Distance Z-axis | mm (inch) | 1000 (39.37) | 450 (17.72) |

| Travel Distance W-axis | mm (inch) | N/A | 500 (19.69) |

| Tool Storage Capacity (Opt.) |

ea | 40, 60 SELECT | 40, 60 SELECT |

| NC System | - | FANUC | FANUC |

Complete set

Standard complete set:

- Installation and maintenance toolkit

- locking device axis Y

- locking device axis Z

- Longitudinal conveyors for removing chips from the processing area

- DSQ-1 packages (includes type II automatic intelligent contouring control, read 200 blocks forward + machine state selection function)

- External M-codes

- Tool unclamping / clamping foot switch

- Set of mounting feet and anchor bolts

- Documentation set

- Operator call lamp

- Periodic self-test function

- Manual pulse generator and control panels

- Rigid tapping

- Intensive internal spindle cooling

- Spindle load indicator

- Conditioner for hydraulic system

- Spindle orientation

- Pallet surface with T-slots

- Work lighting

Additional options:

- Control cabinet air conditioner

- Chip blow gun

- Decoding error codes

- Corner slabs

- Automatic pallet changer (2 pcs.)

- Spindle heads (angular, universal, extension, etc.)

- Automatic part measurement

- Auto power off / power on

- Automatic tool length detection

- Automatic tool changer

- Two-pin tool clamping system

- Chip blower

- Chip conveyor with trolley

- Chip gun

- Tool load monitoring

- Tool life management system

- DSQ-2 Packages (Includes Type II Automatic Intelligent Contour Control, 600 Block Forward Reading + Machine State Select Function, Data Server with 1GB Card)

- DSQ-3 Packages (Includes Type II Automatic Intelligent Contouring with High Speed Data Processing, 1000 Block Forward Reading + Machine State Select Function, Data Server with 1GB Card)

- Leakage prevention device

- System of easy access to the units of the units

- Preset tuning loops

- Intensive chip washout system

- Optical rulers X, Y

- Network filter

- Coolant oil separator

- Increasing the size of pallets

- High pressure coolant through the spindle

- Tool counter

- Workpiece counter

- Coloring the machine in color at the request of the customer

- Software options

You can get additional information from our managers.

Please note that the manufacturer may change the design and specifications without prior notice.