The FANUC ROBODRILL series a-DiB Machining Center is a versatile compact high-speed CNC milling machining Center that easily connects to robotic production chains. The machine is equipped with a spindle with cone number 30 (BT, BBT, SK) and is designed for high-speed precision mechanical processing of parts from various materials, primarily such as aluminum, brass, copper, bronze and other soft materials and light alloys, as well as common and stainless steels, titanium, cast iron, heat-resistant steels and others, without exceeding the permissible forces and machining allowances.

The FANUC ROBODRILL series a-DiB Machining Center is a versatile compact high-speed CNC milling machining Center that easily connects to robotic production chains. The machine is equipped with a spindle with cone number 30 (BT, BBT, SK) and is designed for high-speed precision mechanical processing of parts from various materials, primarily such as aluminum, brass, copper, bronze and other soft materials and light alloys, as well as common and stainless steels, titanium, cast iron, heat-resistant steels and others, without exceeding the permissible forces and machining allowances.

Distinctive features of the FANUC ROBODRILL machine:

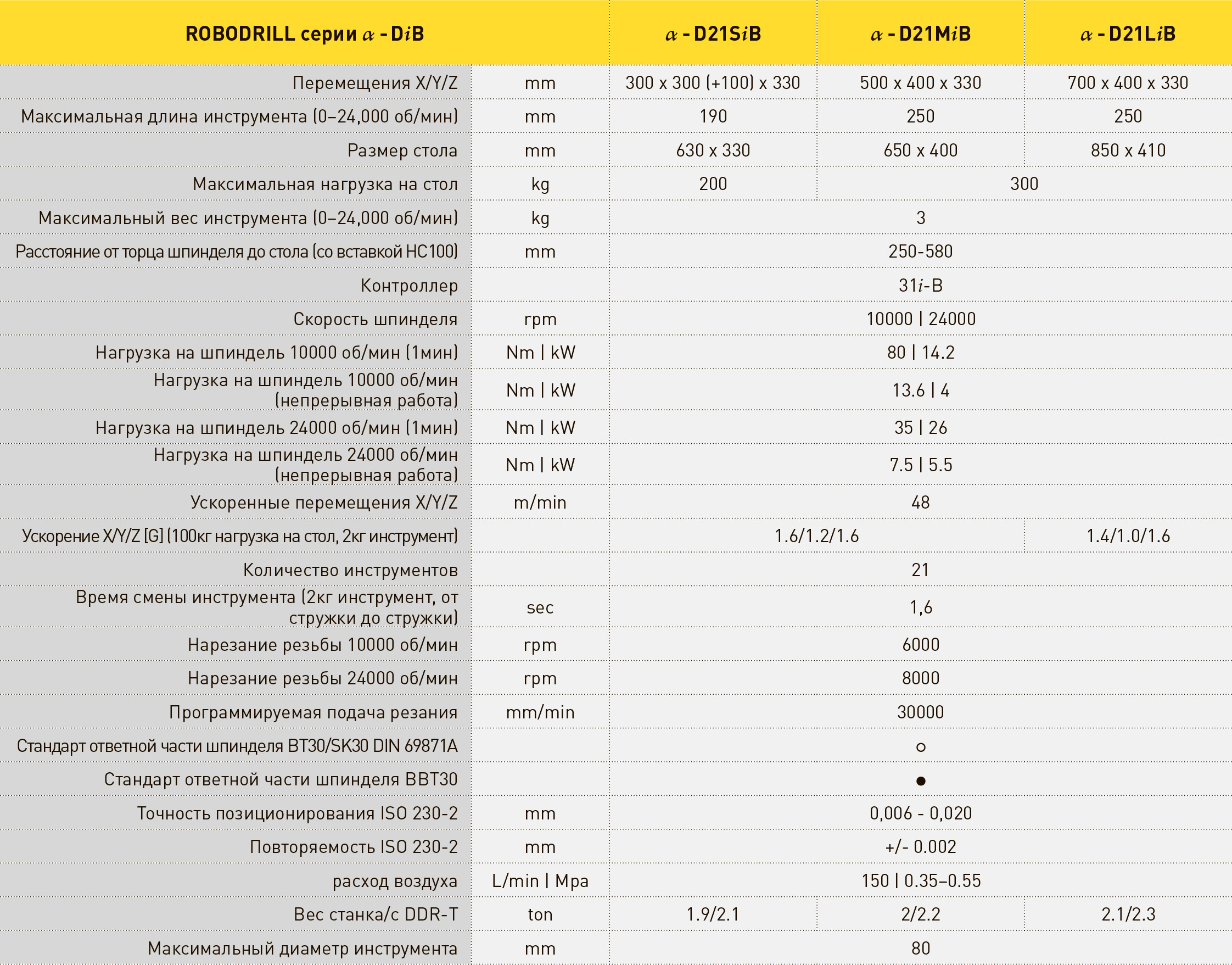

HIGH ACCURACY: The nanometer precision CNC system is equipped with a closed-loop closed-loop nanometer sensor with interpolation functions with nanometer resolution.

HIGH SPEED: positioning acceleration up to 1.6G

HIGH EFFICIENCY: thanks to the high rigidity of the mechanics, high-precision machining with high efficiency is achieved

FANUC ROBODRILL Is Ideal For A Wide Range Of Volumetric Mechanical Processing Problems

Standard:

Standard:

FANUC ROBODRILL For the automotive industry

FANUC ROBODRILL For the automotive industry

FANUC ROBODRILL For the electronics and watch industry

FANUC ROBODRILL For the electronics and watch industry Precise drilling and tapping

Precise drilling and tapping FANUC ROBODRILL For the medical industry

FANUC ROBODRILL For the medical industry