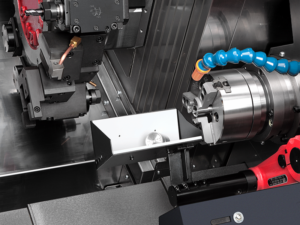

Double-Spindle CNC turning center Miyano (Miyano) BND. The Series' centers allow chucking and bar machining of the front and back of a part.

Specifications

| Model | BND51SY2 |

| Processing performance | |

| Max. working length | 320 мм |

| Max. rod diameter | 51 мм |

| Max. chuck workpiece diameter | 210 мм |

| Spindle | |

| Number of spindles | 2 |

| Spindle speed | 50 – 5.000 мин-1 |

| SP1 nozzle diameter | 52 мм Dia. |

| SP2 | 26 мм Dia. |

| Chuck type | Hydraulic |

| Collet type SP1 | H-S22 bushings |

| SP2 | H-S16, S22 bushings |

| SP1 chuck size and type | 6″ hole type |

| SP2 | 5″ hole type |

| Turret | |

| Number of turrets | 1 |

| Tower Machines | 12 Art. |

| Square turning tool shank size | 20 мм Sq. |

| Shank diameter | 25 мм Dia. |

| Turret indexing time | 0.25 sec/1 pos. |

| Feed rate | |

| Axis travel - Х | 175 мм |

| Axis travel - Z | 435 мм |

| Axis travel - Y | 75 мм |

| Axis travel - B | 530 мм |

| Rapid feed axis - X | 18 м/ мин |

| Rapid feed axis - Z | 20 м/ мин |

| Rapid feed axis - Y | 12 м/ мин |

| Rapid feed axis - B | 18 м/ мин |

| Rotating tool | |

| Number of rotating tools | Max. 12 |

| Tool spindle speed range | 60 – 6,000 мин-1 |

| Power amplification | Max. 13 мм Dia. |

| Crane (steel) | Max. M8 |

| Crane (Al, Brass) | Max. M8 |

| Tank capacity | |

| Hydraulic oil tank capacity | 10 L |

| Oil tank capacity | 2 L |

| Coolant tank capacity | 150 L |

| Dimensions of the device | |

| Height | 1.700 мм |

| Occupied space | 2.560 мм – 1.700 мм |

| Weight | 4.750 kg |

| Engine | |

| Spindle motor SP1 | AC 15/ 11 kV |

| SP2 | AC 5.5/ 3.7 kV |

| Rotary tool motor | AC 2.2 kV 20 Nm |

| Power supply | |

| Voltage | AC 200/ 220 V ± 10% |

| Load | 37 kVА |

| Fuse | 125 A |

| Air supply | 0.5 MPa (5 kgf / см2) |

| Items | BND51SY2 |

| Machining capacity | |

| Maximum work length | 320 mm |

| Maximum bar Dia. | 51 mm |

| Maximum blank diameter chucker | 210 mm |

| Spindle | |

| Number of spindles | 2 |

| Spindle speed | 50 – 5.000 min-1 |

| Draw tube Dia SP1 | 52 mm Dia. |

| SP2 | 26 mm Dia. |

| Power chuck type | Hydraulic |

| Type of collet chuck SP1 | H-S22 Pads |

| SP2 | H-S16, S22 pads |

| Power chuck size and type SP1 | 6″ Through hole type |

| SP2 | 5″ Through hole type |

| Turret | |

| Number of turret | 1 |

| Turret stations | 12 ST |

| Shank size of square turning tool | 20 mm Sq. |

| Diameter of drill shank | 25mm Dia. |

| Turret index time | 0.25 sec/1pos. |

| Feed rate | |

| Slide stroke Xaxis | 175 mm |

| Zaxis | 435 mm |

| Yaxis | 75 mm |

| Baxis | 530 mm |

| Rapid feed rate Xaxis | 18 m/ min. |

| Zaxis | 20 m/ min. |

| Yaxis | 12 m/ min. |

| Baxis | 18 m/ min. |

| Revolving tool | |

| Number of revolving tools | Max12 |

| Tool spindle speed range | 60 – 6,000 min-1 |

| Capacity Drill | Max 13 mm Dia. |

| Tap (Steel) | Max M8 |

| Tap (Al, Brass) | Max M8 |

| Tank capacity | |

| Hydraulic oil tank capacity | 10 L |

| Lubricatibg oil tank capacity | 2 L |

| Coolant tank capacity | 150 L |

| Machine dimensions | |

| Machine height | 1.700 mm |

| Floor spase | 2.560 mm x 1.700 mm |

| Machine weight | 4.750 kg |

| Motors | |

| Spindle motor SP1 | AC 15/ 11 kW |

| SP2 | AC 5.5/ 3.7 kW |

| Revolving tool motor | AC 2.2 kW 20 Nm |

| Power supply | |

| Voltage | AC 200/ 220 V ± 10% |

| Capacity | 37 KVA |

| Fuse | 125 A |

| Air supply | 0.5 MPa (5 kgf/ cm2) |

Complete set

Standard complete set:

- Locking the front door of the safety guard

- Coolant system with chip tray

- Full protection against coolant splash and chip spread

- Hand tool kit (including small service tools)

- Leveling screws and plates

- Machine operation and maintenance manual

- Safety decals

- Work area lighting

- Standard set of tool holders

Optional Accessories and Options:

- Spindle collets, special chucks

- Optional tool holders and drive units

- Systems for automatic unloading / loading of parts

- High pressure coolant systems

- Optical rulers

- Active tool control and sizing systems

- Blow-off / flush / removal / transport systems

- Built-in graphics editor

- Tool load monitoring

- CNC system options

- Software options

You can get additional information from our managers.

Please note that the manufacturer may change the design and specifications without prior notice.

Part types

Please note that the manufacturer may change the design and specifications without prior notice.

Design and specifications are subject to change without prior notice.