High-precision lathe Artank GN-3200W.

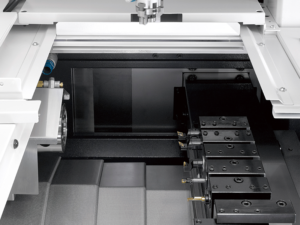

• CNC lathe with 2 movable linear turret heads and 2 spindles.

• The left and right symmetrical linear-movable revolver heads with the corresponding Art. Independently perform simultaneous machining, parallel to the 2 spindles and 2 Linear Art. Art.

• High fidelity Art and minimal footprint and high Art speed are maintained.

• Width of Artank: 1 400 mm \\ Occupied area of the floor: 2.08 m2.

• Increased Z-axis + 20 mm provides more space for tools and chuck.

• The systems of cartridges and tools are compatible with the existing GN-3100W.

• Machining parts in the electronic, automotive and other industries where the highest precision is required. For example, the production of Art injectors.

• The linear X-axis of the turret head and the Z-axis of the sliding headstock are independent slides. This design reduces Art error and distortion to provide more accurate dimensional Art and geometric accuracy.

• When using a single Side Art structure, the reduced mass is accelerated and decelerated, resulting in faster cutting.

• The currently increased Rapid traverse speed of 15 m / min can shorten the start time.

• New conveyor loader increases productivity and reduces costs.

• With fast acceleration / deceleration of the lightweight loading platform.

• Fast start Art 154 m / min on axis X.

• Provide 4 types of loading system to save costs and to achieve high Art.

High-precision compact lathe Artank with CNC GN-4200

• Compact high-precision lathe Artank with CNC.

• Traditional “Basic Design for High Precision Art” is the Ocean Cincom tradition.

• Adopted integrated Art-structure of the Artank base with air cooling and thermal symmetry.

• Spindle with high iron and low spindle head and spindle head, susceptible to heat.

• Focused on ultra precision machining of small length parts.

• The layout tool allows you to use an extended stroke of 300 mm with X-Axis direction. (250 mm)

• FastArt soonArt forward to reduce the processing time (1.5 times), speed up the work of a conventional Artank.

• Increased Efficiency of Hardware Automation - This is an Artstandard High Speed Portal Loader.

• The compact economical space of the Art Tank is 30% smaller than that of the previous model.

• Can be fitted with a tailstock for processing long shafts with an extension of the processing area (optional)

• An Art system is also available for your needs and robot specifications.

Miyano GN Series

- Max. turning diameter 45mm

- Max. workpiece length 80mm

- Max. motor power 5.5kW

Description

Specifications

| Items | GN-3200 | |

|---|---|---|

| Machining Capacity and Chuck System | ||

| Power Chuck | Pneumatic | 3″(4″) Precision Chuck |

| Diaphragm Chuck | Pneumatic | 4″ |

| Maximum diameter of Collet Chuck | Stationary(with Pad) | ø35mm |

| Pull type(with Pad) | ø40mm | |

| Maximum Machining Length | 50mm | |

| Spindle | ||

| Spindle motor | 15min./cont. | 2.2/1.5 kW |

| Spindle Speed Range | 80 – 8,000 min-1 | |

| Turret | ||

| Type of Turret | Horizontal Linear Turret | |

| Shank Height of Square Turning Tool | □10mm, □12mm, □16mm | |

| Diameter of Drill Shank | ø20mm | |

| Slide Travel | X axis | 180mm |

| Z axis | 200mm | |

| Machine Dimensions | ||

| Machine Height | 1,600mm | |

| Spindle Center Height | 875mm | |

| Floor Space(Width × Length) | 700mm×1,460mm | |

| Machine Weight(machine only) | 1,500kg | |

Complete set

Standard complete set:

- Locking the front door of the safety guard

- Coolant system with chip tray

- Full protection against coolant splash and chip spread

- Hand tool kit (including small service tools)

- Leveling screws and plates

- Machine operation and maintenance manual

- Safety decals

- Work area lighting

- Standard set of tool holders

Optional Accessories and Options:

- Spindle collets, special chucks

- Optional tool holders and drive units

- Systems for automatic unloading / loading of parts

- High pressure coolant systems

- Optical rulers

- Active tool control and sizing systems

- Blow-off / flush / removal / transport systems

- Built-in graphics editor

- Tool load monitoring

- CNC system options

- Software options

You can get additional information from our managers.

Please note that the manufacturer may change the design and specifications without prior notice.